Robots vs. lasers sounds like a good time for any kid who loves sci-fi and technology. For Paul Armstrong, an engineer in the NIF & Photon Science Directorate, it’s his reality. By day, he heads up an experimental team working on advanced laser applications; in his spare time, he guides ambitious high schoolers on a collision course with a worldwide robotics tournament.

In 2019, Armstrong took his middle-school-age kids to the Lab-sponsored Tri-Valley Innovation Fair, where his daughter sparked an interest in robotics — unbeknownst to him. When she arrived at Livermore High School in the fall, she joined the school’s FIRST Robotics Competition (FRC) team and was learning how to design, build and operate a robot with them by the time 2020 began. She didn’t talk much about it and her father hadn’t connected her new interest with the visit to the Innovation Fair.

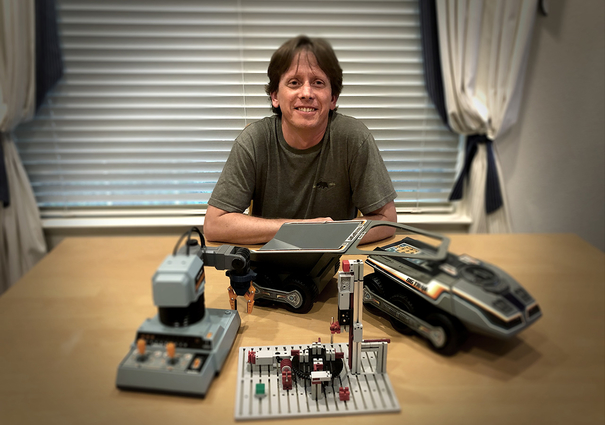

Armstrong had loved building early Lego-style robots with his Commodore 64 computer in 1980s Klamath Falls, Oregon. He turned to lasers later, but his first love was robotics. When the call came, he naturally agreed to serve as a parent chaperone for the March FRC competition in Fresno.

“The competition was the first time I was going to be exposed to FRC and see what they had built as a team,” he said. An advance team of about five people loaded the team’s robot into a truck and began down the road to Fresno. They arrived expecting to unload the robot and build a custom pit to modify and repair it during competition — but they found a sign on the door that the event had been canceled.

“When you understand how much effort and work went into that robot, that is truly sad,” he said. “It was crushing.” Armstrong spent the 2020 COVID-19 lockdown updating his old Commodore 64 robots into a modern Arduino platform. Even a year later, as much of the U.S. was reopening, California schools and Livermore High’s FRC team, GravitechX, were in no shape to compete.

“Our team and most FRC teams are very student-centric, student-run,” Armstrong said. “The students are responsible for everything, which includes teaching new recruits. The upperclassmen teach the freshmen and sophomores their chosen discipline: mechanical, electrical, software or business.”

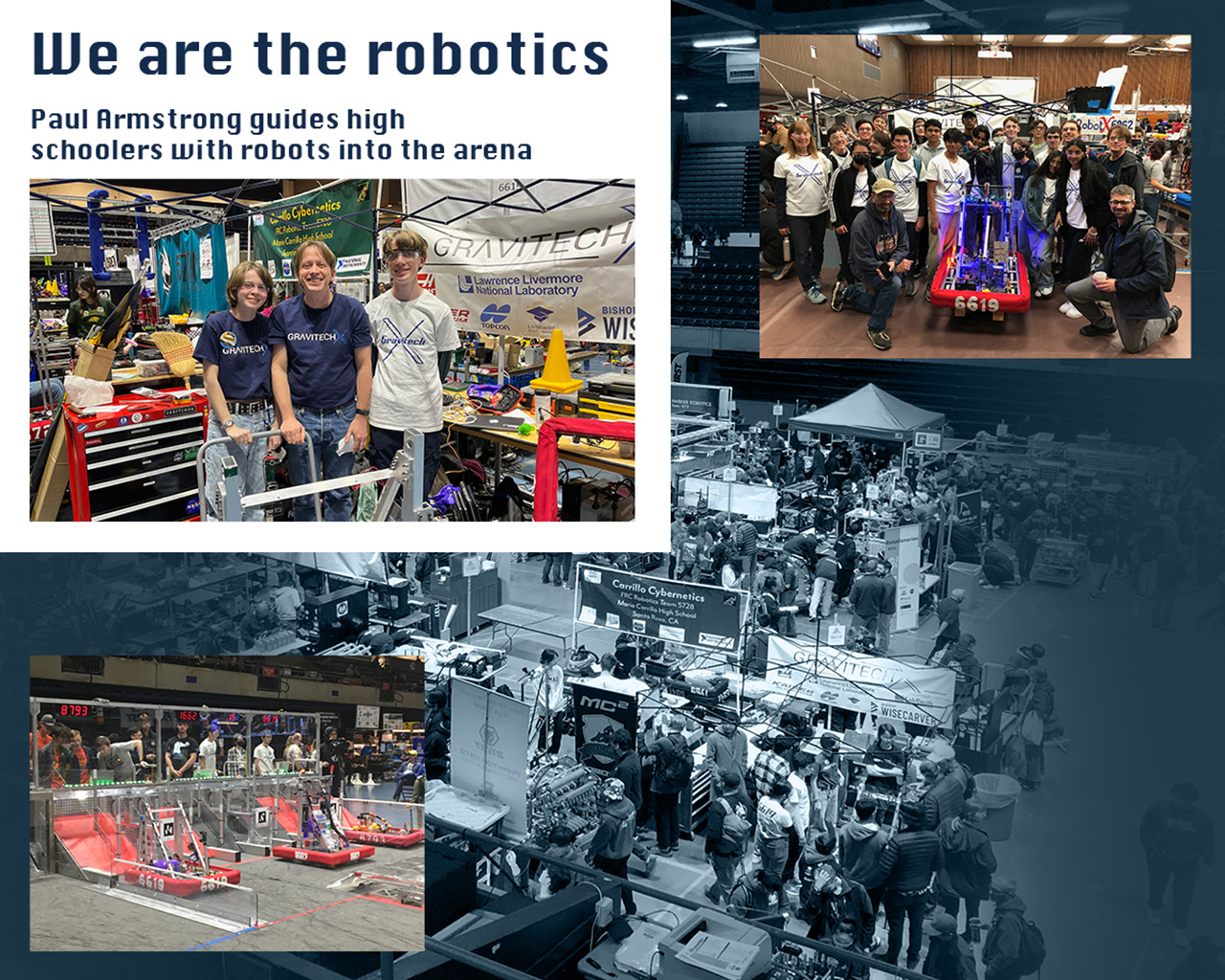

By the time some semblance of normal had returned, the team had lost two classes of experience to graduation and was down to only four people. In stepped Armstrong as a mentor — and his son as a new recruit to reach the required team size of five. Later in the school year, the team had grown to more than 20 students.

“As a mentor, I’ll drill a few holes,” Armstrong said. “but it’s really watching and making suggestions. I’m not saying, ‘do it this way, or move, let me do it,’ but saying, ‘you should consider using an accelerometer to do that, instead of a gyroscope.’”

Each January in a worldwide livestream, FRC announces the type of task each team’s robot will have to complete at the tournament competitions beginning in March. In 2022, that meant picking up and dropping basketball-sized tennis balls into goals of various heights with a robot that can draw no more than 125 amps of power, be no more than 5 feet tall and weigh as much as 125 pounds. The robots have to run themselves for the first 15 seconds of each match, followed by a two-minute, 15-second semiautonomous phase. For the last 30 seconds, more points can be scored by completing a separate task. The matches are jarringly quick and improving your team’s robot can be just as frantic.

“The pit that first year was a very intense place. I had a fitness tracker on; I burned almost 4,000 calories,” Armstrong said, “and took 5,000 steps.”

But this is not Pacific Rim or BattleBots; FRC competitions do not ask the robots to try and fight their way through each problem. (“It’s not combat robotics, but it is full-contact robotics,” Armstrong said.) The GravitechX team strategized to focus on the low goals and defend against their opponents seeking the high goals; other teams also could cater to a secondary task like building their robot to be able to climb a set of monkey bars toward the end of each match. Winning teams from regional events all over the globe earn invitations to the world championships in Houston.

“I can’t say enough about the creativity and the knowledge that these teams exhibit, he said. “It’s astounding. It gives you a lot of confidence in the future.”

Armstrong’s daughter — now the team captain — had led GravitechX from concept to competition in eight weeks with some help from her dad and brother. While the team did not advance out of the 2022 regional, the Armstrong family had saved the team from folding and brought it back to the FRC arena.

Having a growing group of young people with experience in science and technology isn’t a bad return on investment for Lawrence Livermore National Security, which operates the Lab for the U.S. Department of Energy. LLNS is a sponsor of GravitechX, along with several others, through its Community Gift Program.

“I can’t figure out a better way to get kids interested in STEM,” Armstrong said. “I can’t figure out a better way to do it. By the time they come out of this program, the team leads — the mechanical lead, the software lead, the electrical lead — have now led a full engineering team, with deliverables, metrics, the whole nine yards.”

It’s another way of saying they get the kind of experience that might fit in perfectly at LLNL.

– by Ben Kennedy